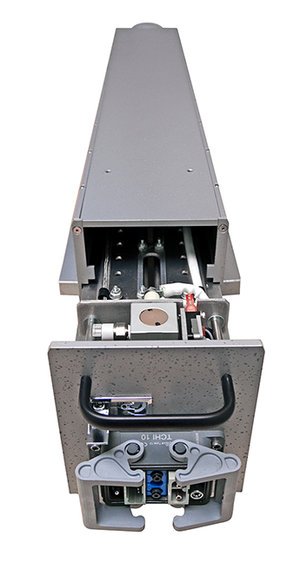

Minimax UV SERIES

Economical. Productive. Efficient. Powerful.

Providing the highest throughput for narrow to mid-web applications, Prime’s MINIMAX UV Series was engineered utilizing advanced CFD software to optimize heat management enabling the reduction of cooling air while guaranteeing optimal UV lamp performance. Prime’s innovative reflector geometry boosts UV dosage to ensure full cure while reducing energy required. Lower maintenance time, money and energy consumption while maximizing UV energy at the substrate…a winning combination!

Product Features

High-Intensity UV Lamps: Auto-adjusts: 125 - 600 wpi (50 - 240 wpc)

Power Driver Types available include Electronic, Electro-Magnetic Ballast and Controlled Ferroresonant Ballast.

Includes Variable Frequency Driven air blowers to minimize power consumption.

-

UV Type: UV Arc Lamp

Cooling Method: Air

Max Power Up to 30” (762mm): 600 wpi (240 wpc)

Max Power Up to 36” (914mm): 500wpi (200 wpc)

Dimensions:

L: Variable

W: 134 mm

H: 175 mm

Power Levels: 4/6/8 or 1%

Power Driver Type: Electro-Magnetic Ballast, Controlled Ferroresonant Ballast, Electronic

Lamp Type/Emission Range: Medium Press Mercury, Iron Additive, Gallium Additive

Reflector Types: Optimum Reflectivity, Highest Reflectivity, Dichroic

Remote Access Maintenance: Yes

UV Measurement: Continuous/Spot

PLC - Standard: Beckhoff

HMI Type: Prime Premier (7”), Prime Premier XL (16”)

Process Control Option: Ensure GMP Compliance

-

Nitrogen Inertion Air Filtration

Chilled Plate or Roller

PLC Type (Siemens, A-B)

Power Drivers

UV Lamp Types

UV Reflector Types

-

Prime UV-IR provides various UV Arc lamp solutions for every printing, coating, and converting application. All of Prime UV-IR's UV systems are custom designed to meet and exceed our customer's expectations. Prime UV-IR is able to supply lamp systems as small as a 6" single lamp system up to multi-lamp 118" UV systems, and everything in between.

-

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.