LEDMAX-IP2 Water-Cooled

Product Features

Premiere HMI Controls: Prime HMI Controls optimize the performance of the UV LED System and reduce energy consumption!

Works at a wide range of Optic Profiles: From 10 mm to 150 mm via R24, R46, R610, R1015

High-Intensity UV Lamps: Auto-Adjusts 0%-100%

Cure UV Chemistry at the Highest Process Speeds: Mercury Free

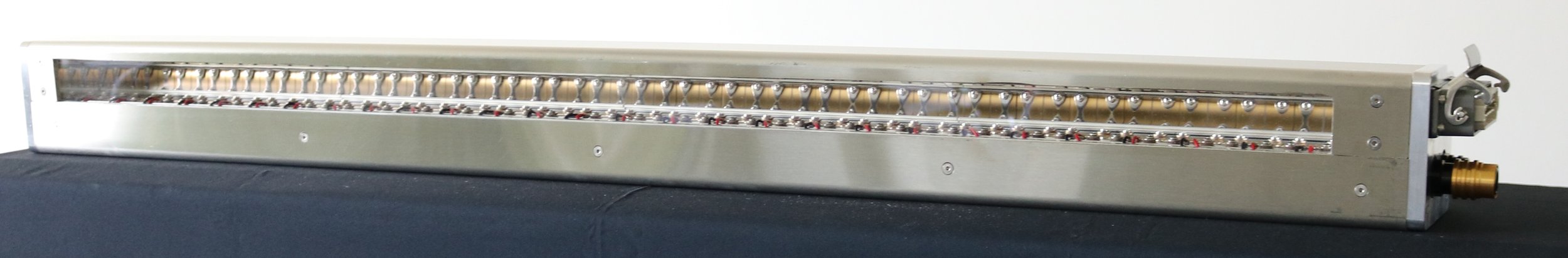

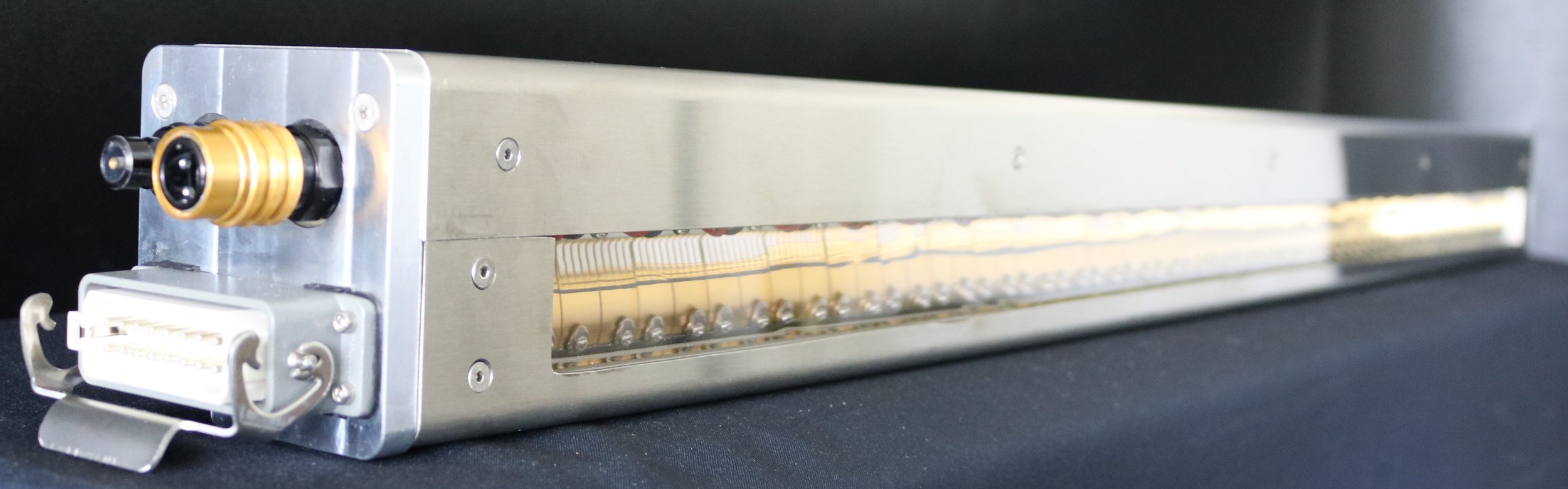

Prime’s LEDMAX ip2 uv Light Engine

Innovative reflector geometry boosts UV dosage to assure full cure while reducing energy required. This reflector geometry also ensures top process speeds at product distances ranging from 5mm up to over 100mm.

Prime’s customized optical package captures the UV LED Energy to further increase UV LED irradiance and improve light distribution uniformity. Not only reducing the number of LEDs required, Prime’s custom UV glass compositions decrease required drive current while maximizing UV energy. Cure quality is improved while reducing capital and operating costs.

The High Intensity chips are cooled via water-cooled technology coupled with controls to ensure the longest chip life available. This Innovative Chip design guarantees chip life of up to 20,000 hours.

Prime’s LEDMAX IP2 Diode UV spectral energy range 365, 375, 385, 395, 405

Manufactured utilizing the finest LEDs available to ensure complete cure at top process speeds. These LEDs not only provide highest peak irradiance but ensure stability and consistent cure uniformity across the substrate.

Prime’s LEDMAX IP2 Light Engine is engineered to allow the flexibility of using either specific Diodes or a custom designed Diode package to best match UV output to specific UV chemistry requirements. The IP2 Series ensures the maximum level of UV emissions regardless of UV spectral range required.

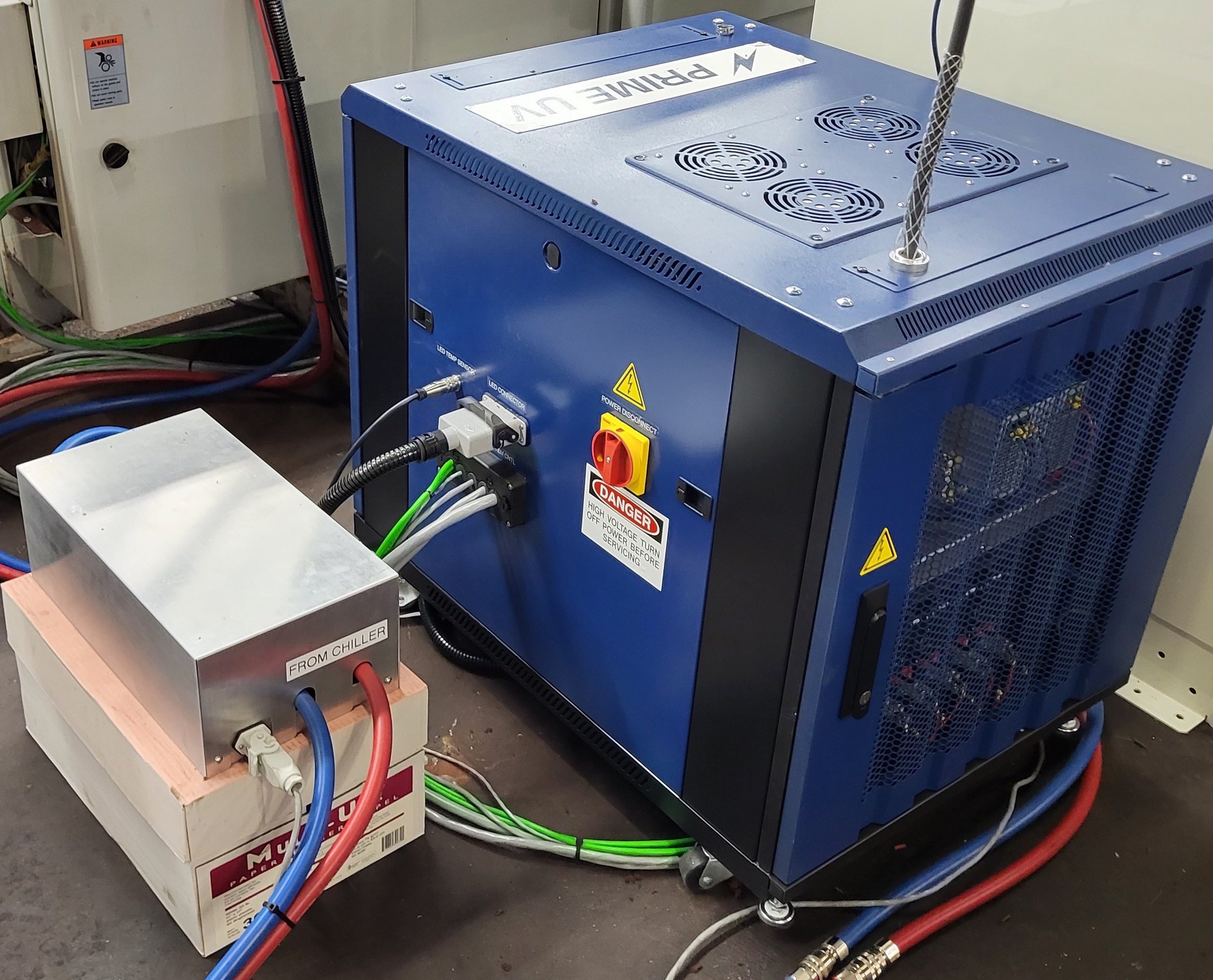

Prime’s premier operator interface

Prime’s visionary control technology safeguards your production process. Continuously monitoring critical UV system data, Prime’s PREMIER control platform automatically alerts users if adverse conditions arise during your production process.

A wealth of information is available not only at your fingertips but from the other side of the world through a simple ethernet connection. Remote access not only for you but for our service department to remotely view all operating conditions and make service recommendations.

prime’s ledmax ip2 power driver

Optimizing performance and reliability/ Prime’s solid-state IP2 power driver provides peak power efficiency to the IP2 UV Light Engine and provides ease of installation and service. The P2 driver uses state-of-the-art electronics providing step-less UV power ramping to auto-match process speed.

Engineering UV curing solutions to the Graphics world for 30 years, Prime’s IP2 Light Engines may be customized to meet specific product & chemistry requirements allowing ultimate flexibility.

Water cooled to deliver the highest UV power available, Prime’s IP2 UV LED Cassette delivers maximum UV energy to materials that have a large Working Distance from the UV cassette commonly found in a Sheetfed Press delivery section.

-

UV Type: UV LED

Multiple Zones: Yes

Cooling Method: Water

Max Power Up to 80” (2032mm): 75 wpi (33 wpc)

UV LED Zones: Match Product Width

Power Levels: 1% Steps

Power Driver Type: Solid State DC

UV LED Chip Emission: 385 Standard

Reflector Type: Highest Reflectivity

Working Distances: 10 mm-150 mm via R24, R46, R610, R1015

Remote Access Maintenance: Yes

UV Measurement: Spot

PLC-Standard: Beckhoff

HMI Type: Prime Premier (7”), Prime Premier XL (16”)

Compliance: RoHS, CE

-

Nitrogen Inerted UV

Chilled Plate or Roller

PLC Type (Siemens, A-B)

UV LED Chip Emission: 365, 375, 395, 405

-

Innovative reflector geometry boots UV dosage to assure full cure while reducing energy required. This reflector geometry also ensures top process speeds at product distances ranging from 5mm up to over 100mm.

Manufactured utilizing the finest LEDs available to ensure complete cure at top process speeds. Visionary control technology safeguards your production process. Prime’s solid-state IP2 power driver provides peak power efficiency to the IP2 UV Light Engine.

-

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.