sheetfed offset uv printing Applications

Commercial & Packaging Offset sheetfed printing typically uses conventional inks which are either water based, soy based or solvent based. For these inks to properly dry additional drying time is required. The additional time required varies tremendously based upon such factors as ink coverage, ink type, substrate type and press room conditions. In addition, during this drying time chemicals are released into the environment and absorbed into the substrate resulting in dot gain and potentially distorting the image and the text.

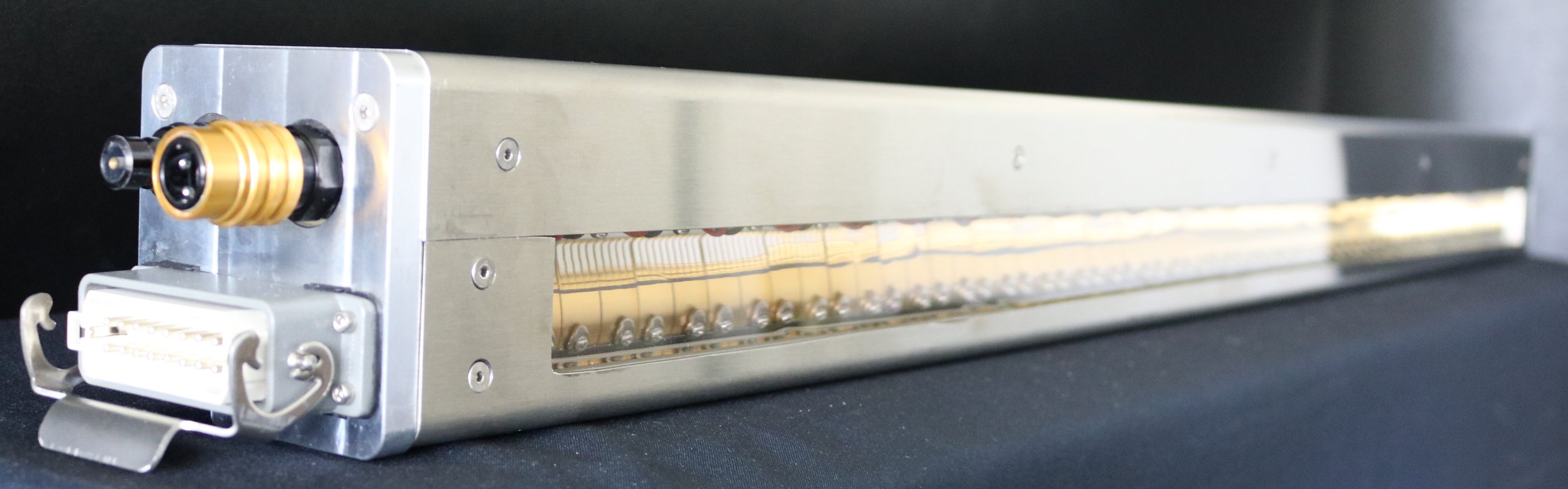

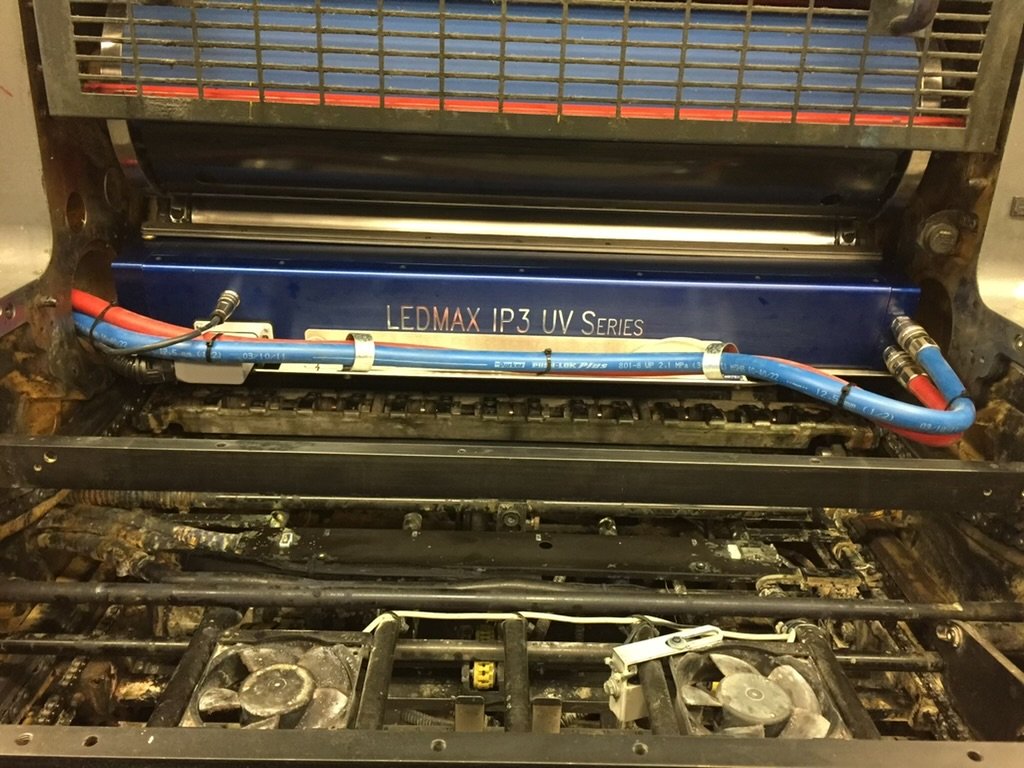

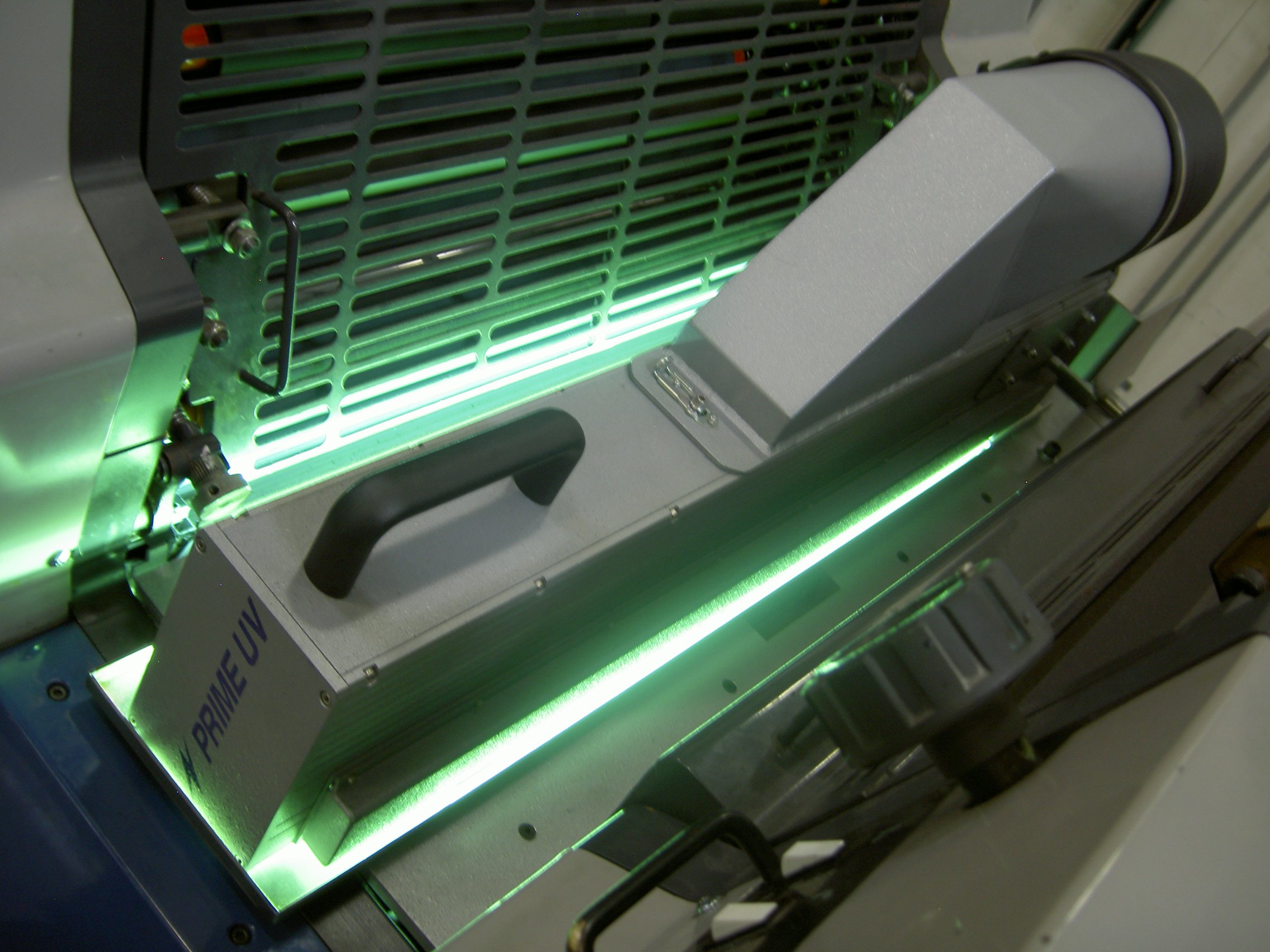

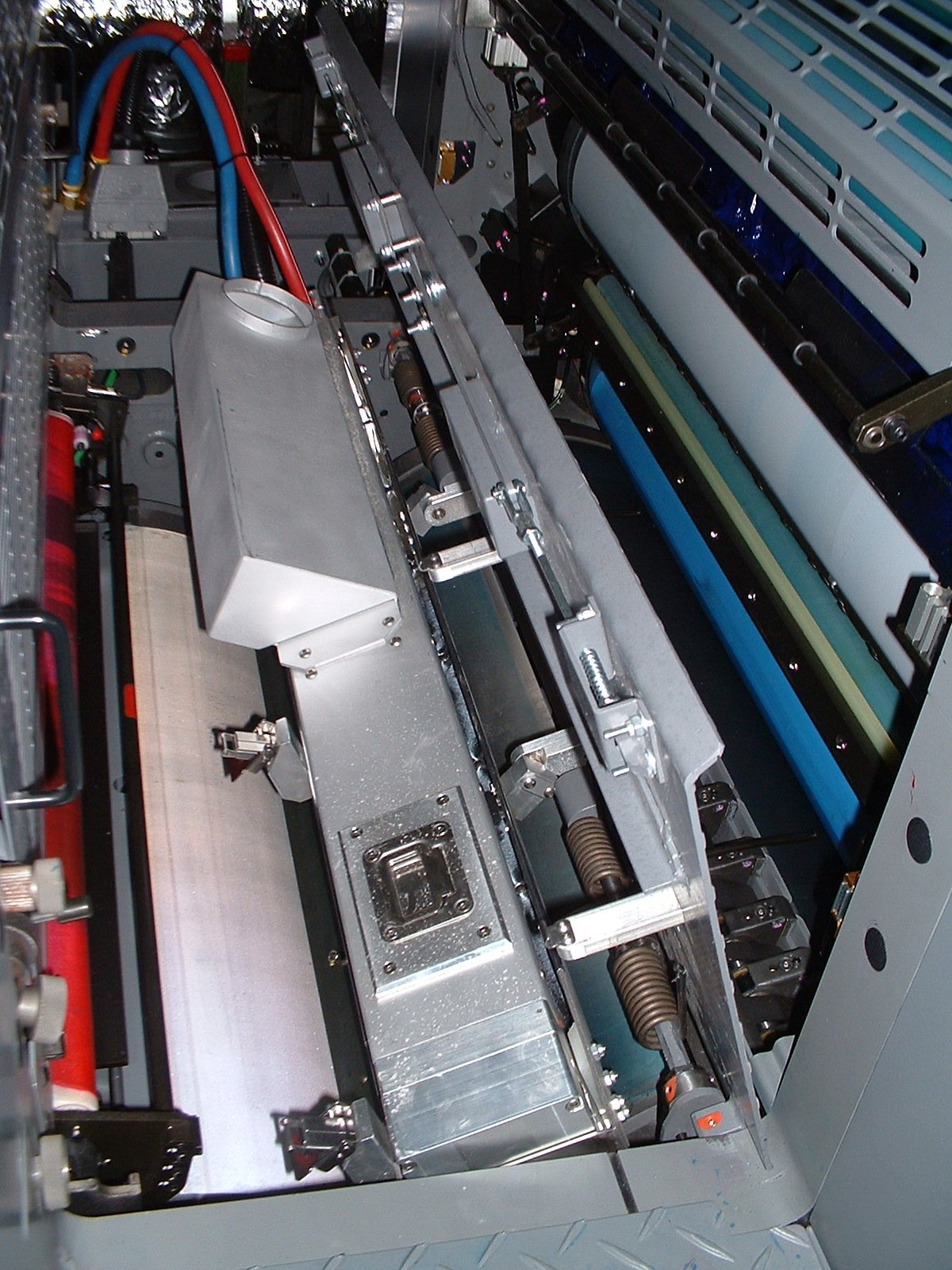

However, UV inks, when exposed to UV energy, dry immediately. The photo-initiators in the UV ink react to cause the crosslinking (polymerization) of reactive monomers, oligomers and ink pigments located within the UV ink. The liquid UV ink turns solid when cured and produces zero emissions.

UV sheetfed Offset printing advantages include:

Sharper images and more vibrant color due to less dot gain.

UV inks are more scratch and scuff-resistant.

Print on a wider variety of substrates including plastics and foils.

Immediate curing (drying) of printed product – eliminate post-print drying time.

Process printed products immediately such as scoring, die-cutting, etc.

Visual and tactile UV coatings can be applied in-line on press.

Eliminate issues with ink adhesion, ghosting and piling.

No need for additional coatings or laminates for print protection.

Better for the environment by reducing energy consumption and reducing the production of VOC’s.

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.