UV LED curing Systems

UV LED Systems provide many benefits such as lower energy consumption, little moving parts to replace, instant on-off capability and compact in size.

WHAT IS UV LED?

LEDs are Light Emitting Diodes which were first created about 50 years ago.

LEDs are used in an endless amount of components and applications: Computers, watches, clocks, PLC’s, switches, lights, and so many others. UV LED: LED which emits UV ENERGY!

Major differences between UV LED Systems and most UV LAMP Systems include:

Unlike a standard UV lamp, UV LED output energy specific: 365, 375, 385, 395 or 405nm.

INSTANT ON – OFF

No waiting time to heat up and cool down.

No Shutters required – few moving parts.

ELIMINATE UV LAMPS

No Mercury – No disposal concerns & less waste

Lower long term replacement costs

UV LED chip life – 20,000 hours estimated vs. 2,000 hours (traditional UV bulbs)

Less cooling required.

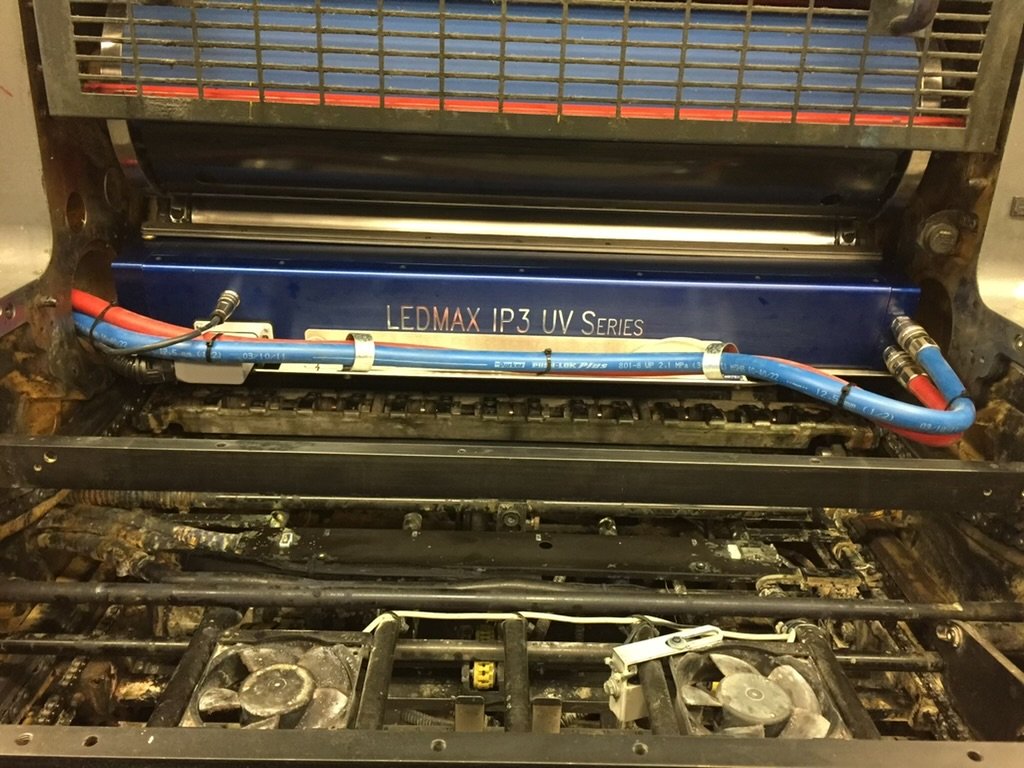

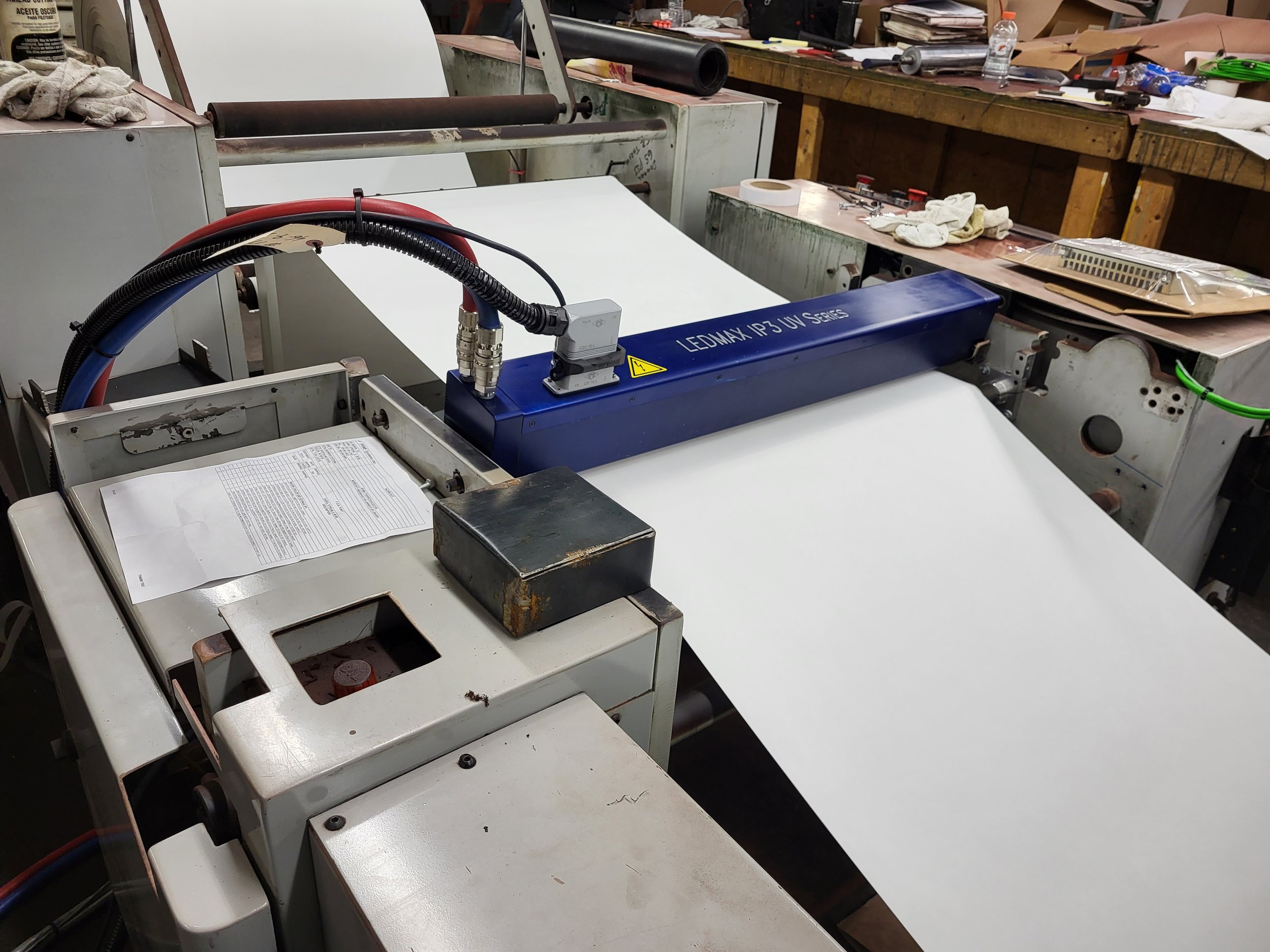

More compact

Easier to install

No air exhaust required

Heat is generated by the LEDs, but most is removed via back side of the UV LED COB (“Chips On Board”)

Since less overall IR energy produced less penetration of heat into substrate

UV LED COBs are CASCADABLE

If not running full substrate / product width, user may have the ability, dependent upon UV LED System, to turn off COBs not needed.

Saves more energy and LED COB life.

MAJOR BENEFITS OF UV LED & UV LAMP SYSTEMS

WHEN RETROFITTING UV TO EXISTING PRESS…

INSTANT DRYING - Press Productivity Increases & Extends Life of Press

Direct to Finishing.

Increase post-press productivity 30% and more

No More Waiting for Stacks to Dry

Eliminate issues with scratching, marking and offsetting

Regardless of substrate type and pile size

Instant finishing, bindery, padding, scoring, folding, etc.

Increase plant production capacity

Print more Jobs – Increase revenue without increasing production staff

Possible surcharge for immediate turnaround

Broader product offering & higher product quality

Print on foil boards, acetates, plastics, etc.

Eliminate use of powder

Faster clean up & cleaner healthier facility

IMPROVED PRINT QUALITY & REDUCED WASTE

Richer & deeper Colors

Minimal Ink Absorption

Color pigments remain on top of substrate

Greatest visual dimension to printed images

Images “Pop” off sheet

Not adding to ink provides more consistent color

Start Up Waste Reduced – smaller ink/water window

UV Ink mileage substantially higher than other ink types

Print Incredible ink densities on high hold out stocks

UV Inks Provide Improved Product Durability & Chemical Resistance

ENVIRONMENTALLY FRIENDLY

BENEFITS OF UV LED SYSTEMS OVER UV LAMP SYSTEMS

LESS HEAT DIRECTED TOWARD SUBSTRATE

Greater Substrate Range

Expand product offerings & attract new business

Increase Revenue

Charge a premium for printing delicate substrates

Lower Material Costs

Lighter/thinner substrates

LED UV inks little to no odor so Ideal for sensitive packaging products

Food Items, Tobacco, Cosmetics, Chocolate etc.

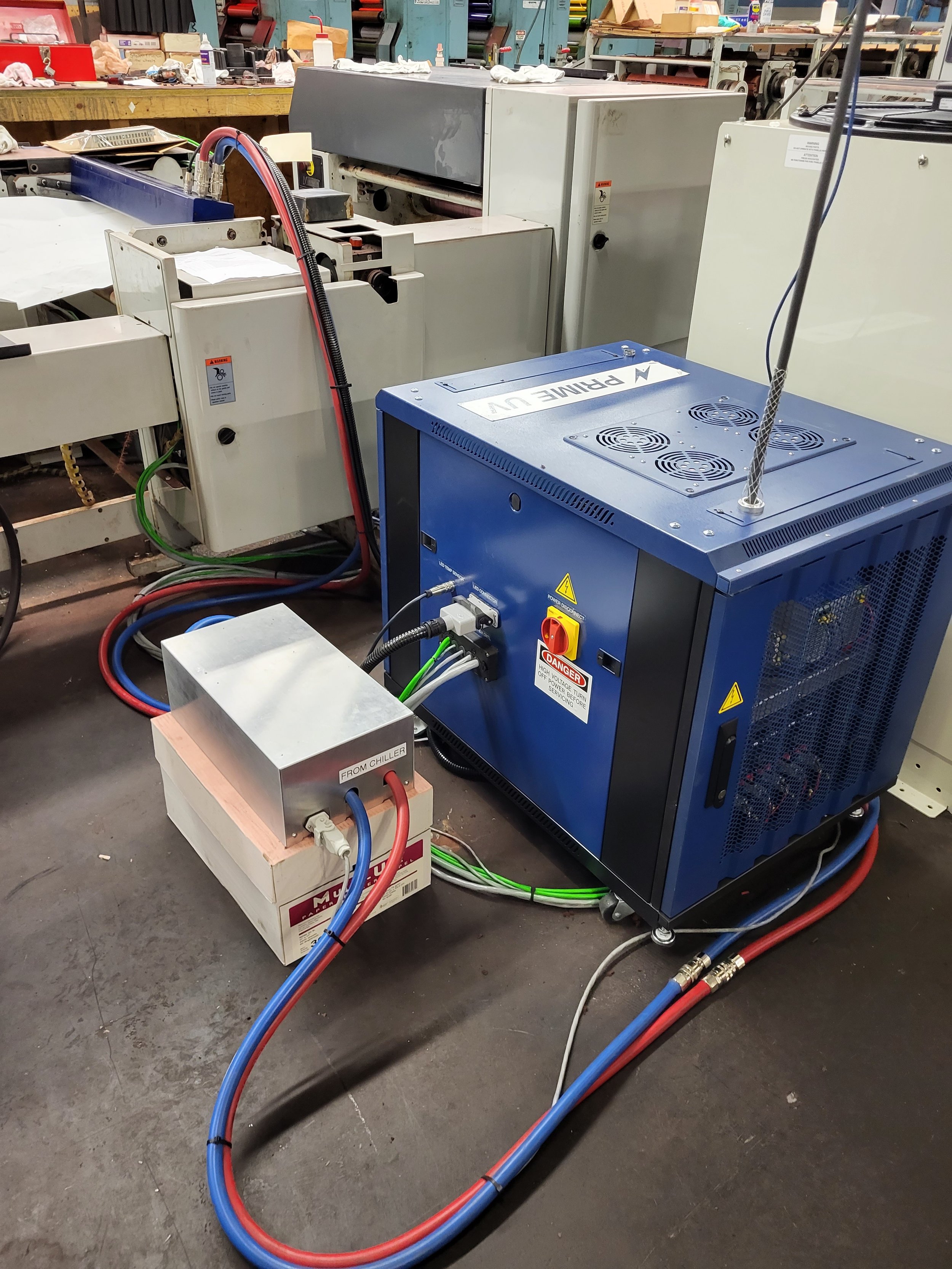

High Powered LED only uses water for cooling

No Air Blowers

Reduces cost & complexity of installation, maintenance & operation, and reduces sound level of UV System operation

Eliminates use of UV lamps

NO mercury & NO ozone generation

Eliminates UV lamp disposal concerns

BENEFIT: ENERGY SAVINGS – 1/2 the energy of traditional UV

Compared with IR or standard Arc Based UV systems

Higher the electrical cost in area, greater the savings

Utility companies in various regions subsidize LED UV Purchase provide substantial rebates for replacing technologies with lower electrical consumption technologies

Lower costs to Air Condition Operating Plant

CONTACT PRIME UV-IR to learn more about Prime’s High Performance UV LED System Series!

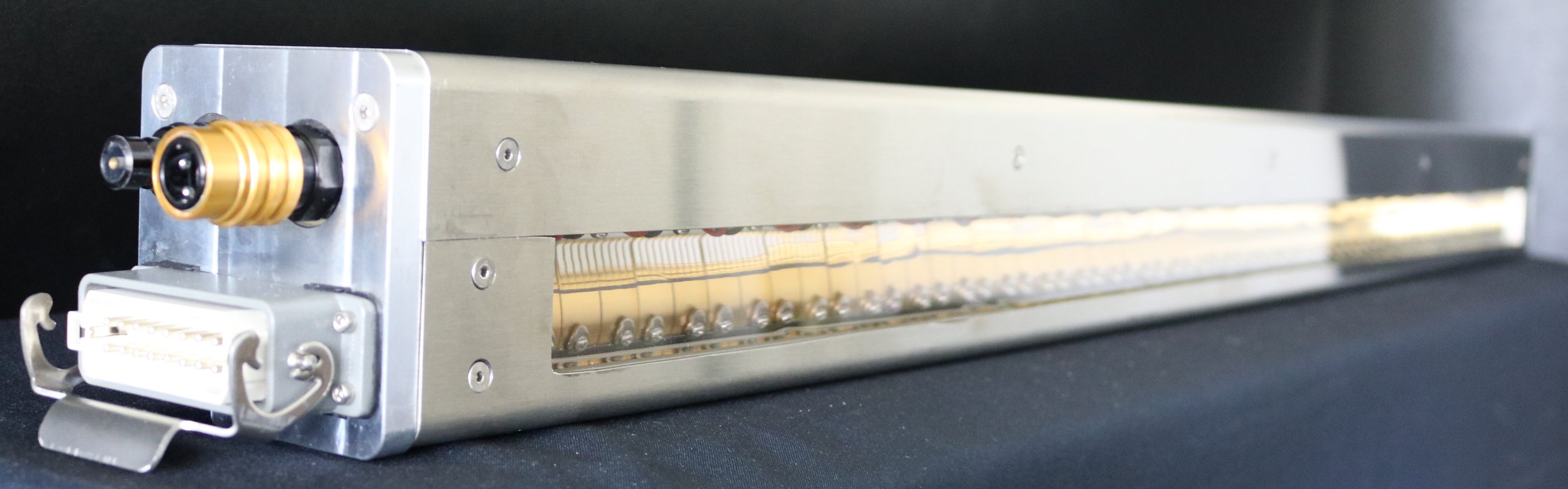

Recommended prime products for this TECHNOLOGY

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.