UV PRINTING Process EXPLAINED

Using UV Chemistry in the printing process is considered UV printing. UV printing is currently done on lithographic, flexographic, screen, rotogravure and digital presses located worldwide.

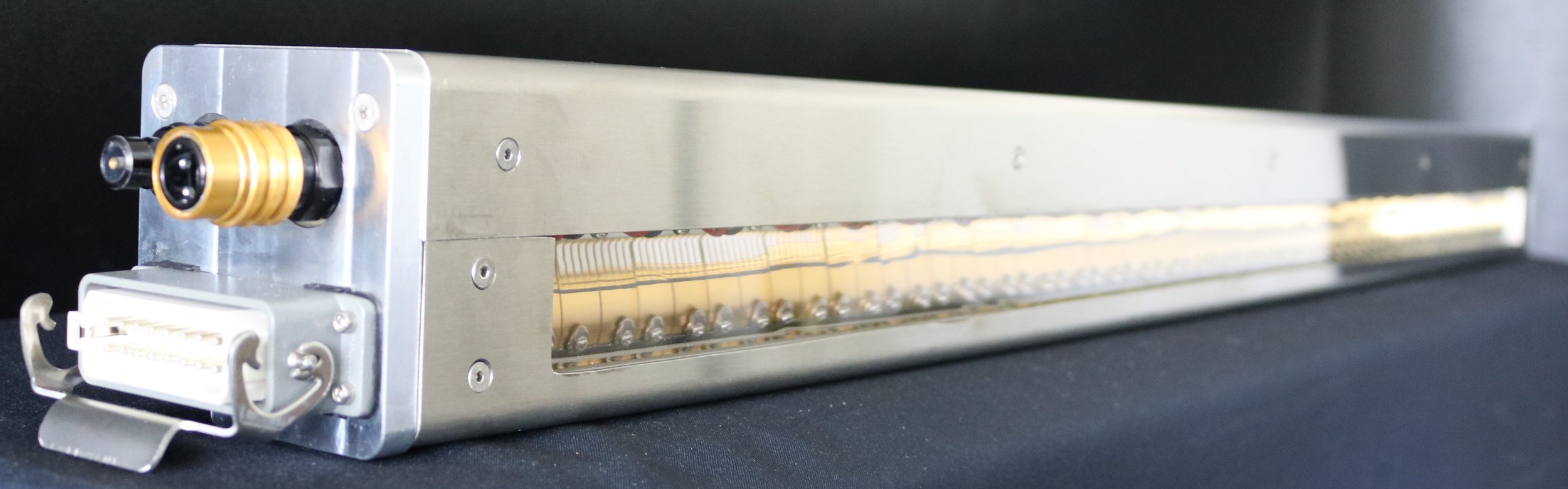

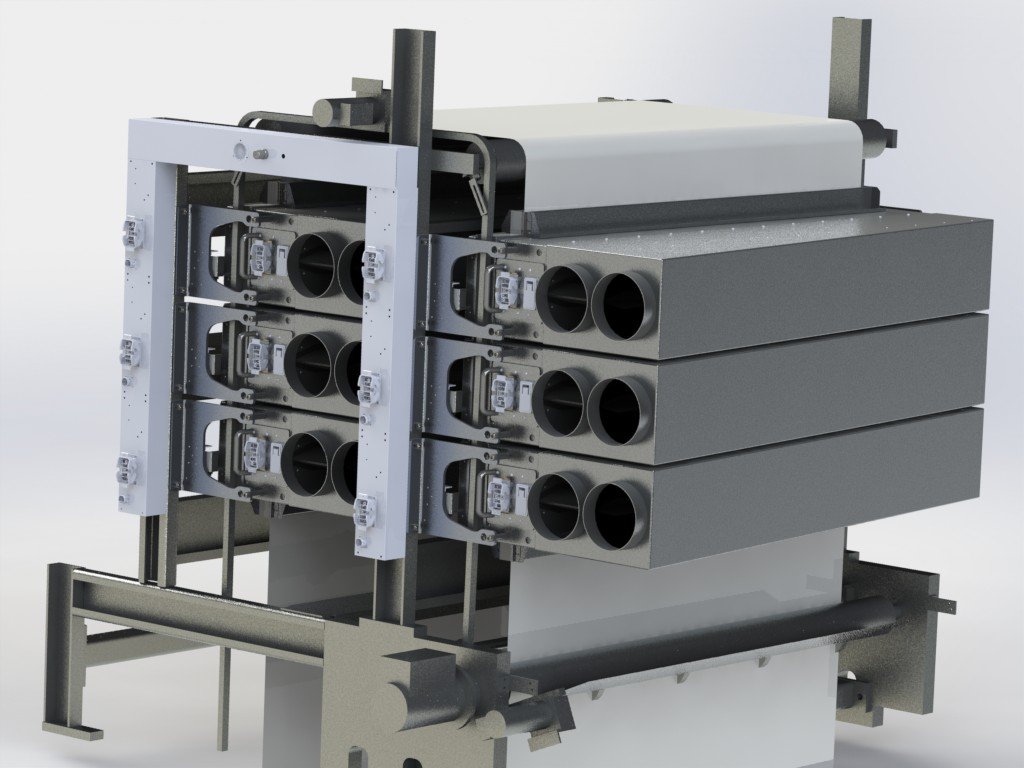

UV printing is a type of printing that uses ultraviolet light (energy) to cure or dry the ink as it gets printed on the substrate surface. As the printer distributes the UV ink on the surface of a material, the material will pass under the UV light (energy) which instantly cures (drys) the UV ink.

UV print technology offers direct printing capabilities onto a virtually limitless range of 3D media, allowing easy and quick product customization. This is one of the reasons why UV printing is used in a wide variety of printing, packaging, converting and industrial applications.

The UV chemistry is applied onto the substrate and when exposed to UV light, the chemistry turns to a solid state from the liquid. Immediate advantages of using UV inks are that UV inks dry immediately and release no VOCs into the environment. UV printing is considered a green technology, safe for the environment and leaves a negligible amount of carbon footprint.

MANY BENEFITS OF UV PRINTING

Undoubtedly, ultra-violet printing is the future of the printing and packaging industry. UV printing technology is economical, ecological and offers the following business-generating benefits:

UV curing eliminates tracking of ink.

Immediate processing – no drying time required. With UV curing, the product can be converted in-line. Fold, bind and ship product same day.

The press operator can increase the speed of the press while eliminating print quality issues.

UV inks can be formulated to be heat resistant. The printer can run products and forms for thermal printers.

A wide variety of specialty UV coatings can easily be applied in-line during print production including UV Protective coating. All of these UV coatings cure instantly.

UV chemistry has zero to little VOCs. UV’s unique no solvent, no water formulation meets the strictest Clean Air Act standards.

Most importantly, the printer can broaden its product line to include a wide variety of nonporous substrates.

Recommended prime products for this TECHNOLOGY

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.